TECHNOLOGIES

Implementing new technologies and accumulating experience,our company has gained a reputation as a responsible domestic producer

of thin glass fabrics for the electrotechnical industry.

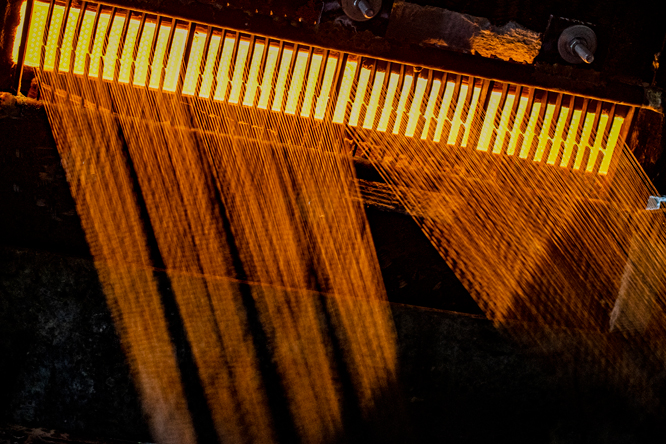

The glass fiber production process starts with the manufacturing of continuous glass fiber.

Glass fibers are obtained by high-speed extraction from a homogeneous glass mass of aluminum boric silicate glass, which is an alloy of various oxides.

In the glass fiber production department, continuous filaments, stretched through the bushing field, are connected in the process of sizing into the strand.

PROCESS OF YARNS TWISTING

At the next stage, the bobbins of glass strands are supplied to the unwinding and twisting department, where the strand undergoes the necessary twisting to increase its strength. Glass yarns are produced at various types of sizing and packing types. We provide yarn doubling of various folds number, any twist direction and the set weight.

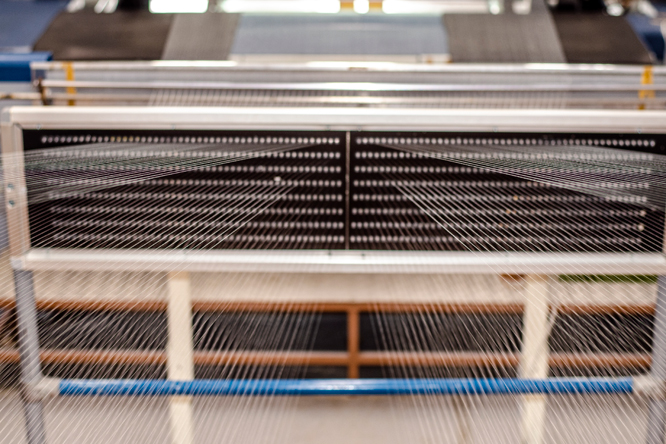

THE PROCESS OF YARN WARPING

In the process warping, yarns from a certain number of bobbins, are wound parallel to each other with the same tension and equal length on the beam. The company uses two types of warping: beam and tape. Warps can be subjected to slashing in order to strengthen the yarns.

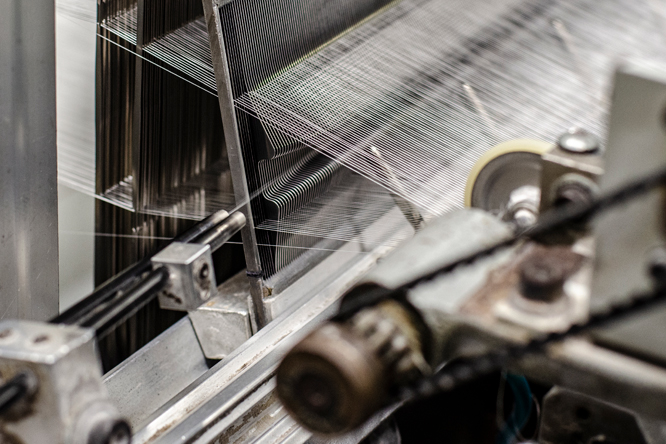

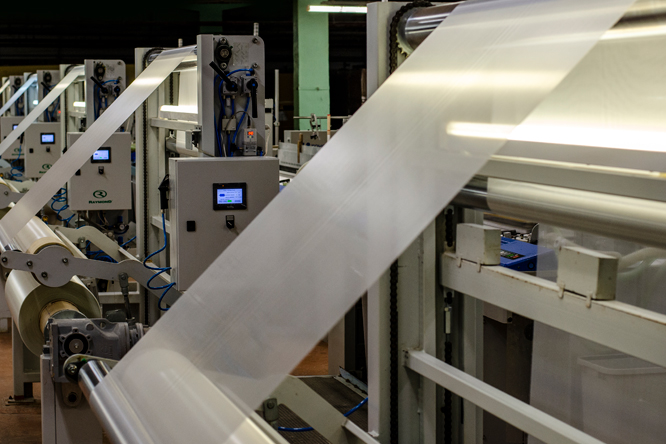

THE WEAVING PROCESS

The weaving process is the interlacing of warp and weft yarns. Modern machines, available in PAO “Astrakhanskoye Steklovolokno” allow to produce glass fabric of uniform structure with width up to 1500mm and the length of the fabric in a roll up to 9000m. At the moment, the range of our products includes the very thin glass fabrics weighing 16 g / sq. m and more. The production of such glass fabrics is a delicate process, sensitive to the impact of all surrounding factors.